info@synthesys.co.uk • +44 (0) 1947 821464

Automotive Systems Engineering

Solution Tour

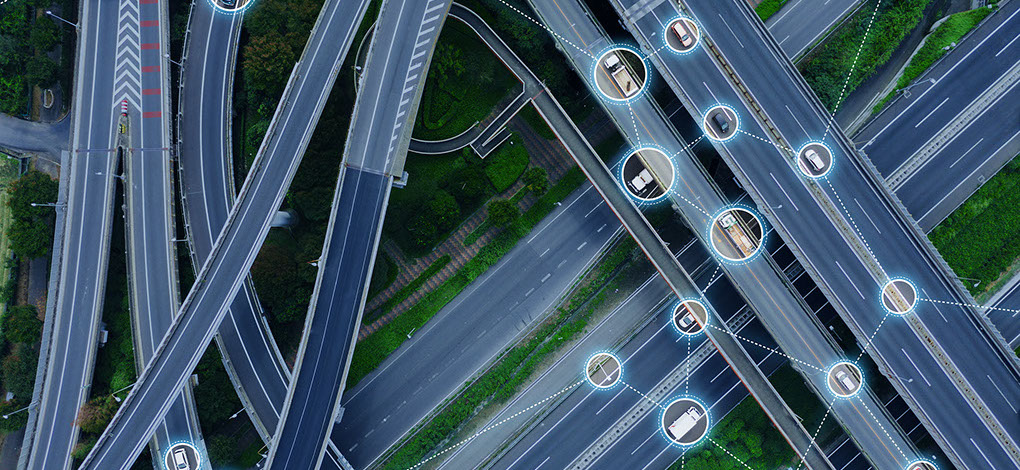

It’s no secret that things are moving fast in the Automotive Industry. As manufacturers consider how to shift towards digital manufacturing, decarbonisation, electrification, connected and autonomous vehicles and green manufacturing, there is huge opportunity and scope for automotive players.

The UK is at the cutting-edge of new automotive technology with arguably one of the strongest global supply chains, boasting 14 vehicle production centres and a large majority of the Tier 1 automotive suppliers.

The UK’s strong manufacturing capability is matched by it’s pioneering technological innovation influence and is home to some of the best-in-class innovators in electric vehicles, lightweighting and battery development.

Navigating Automotive Engineering Complexity

Automotive Engineers build some of the world's most complex assets and nowhere is the complexity of technology more evident than in the modern car. Engineering vehicles with a much greater demand for advanced driver functionality comes with a huge amount of challenges.

Furthermore, the industry needs to consider the various compliance standards: safety (ISO 26262); cybersecurity (ISO 21434); process and quality (Automotive Software Performance Improvement and Capability dEtermination (ASPICE)), and even emergent standards for Artificial Intelligence (AI) such as Safety Of The Intended Functionality (SOTIF).

This shift towards advanced functionality, a more rigorous need to comply and a focus on innovation, calls for a method of work which connects assets, engineering and supply chain operations in an automated and streamlined way.

As the systems developed by the automotive industry grow ever smarter and more complex, many automotive manufacturers have turned to systems engineering as a way to ensure they keep enhancing the value of their products in a more technically demanding market.

Accelerate, Innovate, Comply

Systems engineering is a discipline in its own right, concerned precisely with the insights, processes and tools to enable you to look at a product as a whole. Systems engineering is about drawing on the science of finding patterns in organised complexity, and the analysis of the emergent properties of a whole, rather than the specific behaviour of individual components. It’s a fundamental shift in perspective, based on the idea that looking at the structure of a complex system gives you a better understanding of how the system will behave than you would get from focusing only on the mechanical details.

We specialise in tool-supported systems engineering – providing our automotive Customers with affordable systems engineering services, tools and training to increase their efficiency and effectiveness in delivering solutions.

As an IBM® Gold Business Partner, SyntheSys provides a unique blend of application knowledge, experience and a flexible delivery mechanism, which provides Customers with the right software solution and a deeper understanding of the tools to ensure maximum benefit.

Request a Demonstration

Featured Resources

Maximising Customer Value in Automotive Engineering

There's a delicate balancing act to be struck in contemporary automotive engineering. Customers increasingly demand a more personalised experience, and a bespoke product that reflects and respects their particular needs. For manufacturers and designers, there are certainly opportunities in being able to meet these more specialised demands. This technical article explores how specialist automotive manufacturers can better understand, prioritise and address customer requirements through the use of systems engineering practices.

Engineering for Lean

The automotive industry invented Lean manufacturing, and with the advent of technologies for digital and green manufacturing, supply chain integration and transparency, and more widespread automation of the manufacturing process, automotive continues to be a vanguard of clean and heavily optimised product value streams.

Heavily optimised Lean manufacturing requires stable inputs to remain effective, not just in terms of resources but also in terms of knowledge and engineering objectives. This technical article explores systems engineering in the context of lean manufacturing and fast-paced innovation and how it can provide the clarity and foresight necessary to minimise the risk of project objectives changing during development.

Creating Value Through Collaborative Automotive Engineering

To provide stability, automotive engineering needs processes and tools equipped to manage complexity in an environment of change. Many in the industry are already looking to the techniques and software associated with systems engineering as a way to provide the rigour and stability necessary to take automotive into the next decade. But while systems engineering practices have become widespread with respect to requirements, change has not yet gone as far as it might to better support the future of automotive products.

This technical article explores the idea of ‘collaborative engineering management’ as a means of enhancing the life cycle value of a product by looking at the whole organisational environment through a systems engineering lens.

Electrification and the Automotive Industry: A Systems Engineering View

As we take major strides towards complete electrification on our roads, this brochure considers the development of Electric Vehicles (EVs) and discusses some of the key elements in which systems engineering methodologies and practices can accelerate EV adoption.

Making Automotive Embedded Systems More Agile

When industries turn 'smart', when that threshold of technical complexity is passed, it usually requires of engineering to radically rethink its workflow and practices. When it happened to software engineering in the 1990s, Agile was the result. The automotive industry is getting to a similar position now, and the time has come for it to explore options for how it can adapt to this changing environment.

Automotive Engineering’s Integrated Future

Constant pressure from vehicle manufacturers for price reductions has caused many automotive suppliers to investigate more efficient production processes. Streamlining product design and workflows can be a daunting, time-consuming endeavour, especially in an environment of growing product complexity. This article explores how automotive engineering organisations can meet the demands of more integrated and intelligent automotive systems.

Why it’s Getting Harder to Innovate in Automotive - and what you can do about it

Right now the pressure to innovate in the automotive industry is arguably the strongest it has been in its entire history. Decarbonisation, autonomous vehicles and Brexit are changing regulatory demands, driving up product complexity, and encouraging the industry to invest in digital manufacturing and supply chain integration. This article examines the processes and tools designed to model and anticipate the structure of a system to ensure projects can have assurance from the start that the right thing is being built in the right way, and that the product will interact appropriately with its context.

Customer Success

Jaguar Land Rover Requirements Writing Training

Jaguar Land Rover (JLR) is an extensive user of IBM® requirements management solutions within the engineering business. It was identified that the actual process and methodology for writing requirements within the organisation would benefit from a consolidated and coherent approach. Working with IBM® and JLR, a one-day training course was devised and maintained in the principles of requirements writing, which focuses on the underlying methodology.

Upskilling Over 800 Employees

Want to Hear More?

Start the Conversation

Request a Demo

Request a Free Trial

Subscribe to OptimiSE Magazine

Email: cet@synthesys.co.uk

Telephone: +44 (0) 1947 821 464

A one-to-one demonstration will allow you to see how our tool-supported Systems Engineering approach is helping Engineering organisations across a range of industries manage change. Contact us here.

Put the tools and methods to the test with FREE access to leading IBM®

Engineering Lifecycle Management tools. Evaluate the tools on your own terms. Contact us here.

Would you like more useful content delivered to your mailbox directly? Subscribe below to receive OptimiSE e-magazine here.

Site Map

SyntheSys Technologies

© SyntheSys Systems Engineers Limited - All Rights Reserved

Version 2.2r dated 21 March 2024